Intermediate Level

Now we’ll dig deeper into a few applications

Intermediate Level Syllabus (Processes)

Ready to dig deeper? The Intermediate Level consists of three sections: Relevant Processes, Hardware, and Software for the Fraction Finder.

Intermediate (Processes)

- Short Path Distillation Explained

- Wiped Film Evaporation Explained

- Ethanol Extraction Explained

Our full list of Arometrix applications can be found on our Resources page.

___

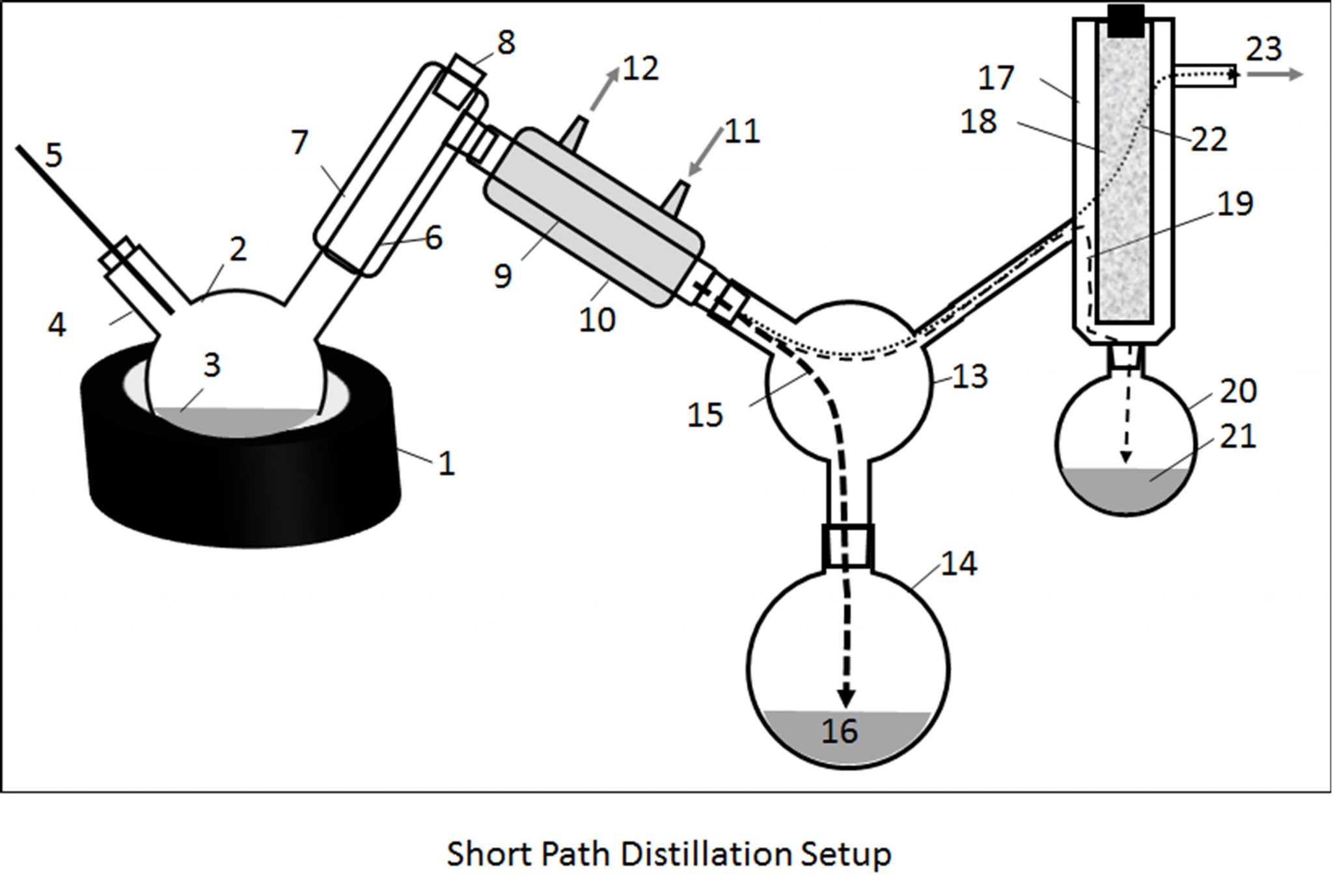

1. Short Path Distillation Explained

Short path distillation (SPD) is a process of extracting individual chemical compounds from a larger material. In this process, technicians are looking to split a material, likely a botanical, into different chemical compounds so that they can keep the useful substances and remove the contaminants. It is called “short path” due to the short distance the chemicals travel through glassware before they fully separate. This process is commonly used for purifying small amounts of a compound, or when working with compounds that become unstable when reaching high temperatures. Examples include organic compounds like solvents and aodic molecules utilized in the life sciences industry for biomedical or biological research and botanical oil refinement.

Every Standard Operating Procedure is different, but the basic steps include:

1. Set the temperature and vacuum level

2. Observe the flow and bubbling action through the head

3. Observe both the rate of flow and color of distillate in the collection flask

4. Determine when to switch flasks

Here is a more detailed set of instructions, including where the Fraction Finder comes in:

1. Set up a clean short path distillation system using the following equipment: Heating/receiving flask – round bottom flasks, Distillation head, Distribution condensers, Short path distillation head, and the Fraction Finder

2. Place the liquid to be distilled in the heating flask

3. Pull a Vacuum below 5 Torr

4. Heat the System: Make sure the large flask no more than 1/2 full on a hot plate at around 180 – 200° Celsius. This will heat up the large beaker

5. Vary temperature to get a steady flow of materials through the condenser, but not so much where it is violently boiling through the head

6. Use the Fraction Finder’s readings to determine when the “Main Body” fraction is flowing through the condenser – when this happens, change the collection flask to avoid cross contaminating the fractions

7. Use the Fraction Finder’s readings to determine when the the “Main Body” fraction is decreasing – when this happens, change the collection flask in order to collect the residual “Tails”

8. Once the run is complete, clean your glassware and set it up for another pass

Diagram of a Typical Short Path Distillation Setup

___

2. Wiped Film Evaporation Explained

Wiped film evaporation (WFE) is a continuous distillation process, in which a rotating wiper sends the distillate onto a heated surface within the system, thinning the material and separating it into two different pathways that are collected in separate flasks. The WFE process is commonly used for the production of refined fragrance, fats, and hemp oil, among other markets.

Basic Steps of a Wiped Film Process

1. Crude oil is fed into a main chamber

2. A spinning wiper sends the distillate onto a heated surface within the system

3. The spinning wiper thins the crude oil to a film to maximize the heat uniformity and thermal transfer of the product as well as to accelerate the heat-up times

4. This results in an efficient, uniform heating process

5. While the heated crude will fall into a flask, the vaporized crude will be sent through a different pathway that is re-condensed and collected.

Currently, in WFE of botanical oils, processors look at the color and viscosity of the fluid to determine the quality of their separation during the process. Processors can control the quality of their process using four parameters: temperature, flow rate, vacuum pressure, and wiper speed (RPM). During the process, processors primarily control and adjust temperature and flow rate, while vacuum pressure and wiper speed are fixed. The current control process is very subjective and based on experience, which is where the Fraction Finder comes in.

Wiped Film Evaporation vs Short Path Distillation

Other methods of refinement such a short-path distillation (SPD) have no feed stream, and thus are considered ‘batch processing’. WFE, however, is a process that is constantly separating, and thus can be operated in either ‘semi-batch’ or ‘continuous’ processing modes. Also unlike SPD, which requires sequential separation of all fractions, WFE separates in parallel, overcoming fundamental speed and efficiency limits of SPD. Furthermore, WFE has no big boiling flask, which reduces the amount of time the crude oil is kept at high temperature. This time reduction significantly decreases the thermal degradation of cannabinoids during the separation process. Lastly, while WFE is known to have higher throughput, this increase comes at a higher equipment cost.

Wiped Film processors manage four different core parameters

1. Flow rate

2. Temperature

3. Pressure

4. Wiper speed (RPM)

___

3. Ethanol Extraction Explained

Ethanol extraction is a relatively quick process that comes prior to distillation. During this phase, Cannabinoids are in the acidic form.

Basic Steps of an Ethanol Extraction Process

1. Filling System – the extractor is filled with ethanol

2. Agitation then Soak Cycle – the extractor is agitated then goes through a soak cycle

3. Full Flow – the flow for recirculation begins

4. Recirculation Phase – Extractor recirculates ethanol over system

5. Emptying System using N2 Gas – Extractor is emptied with nitrogen gas and system no longer chilled

6. Emptying Reservoir – Extractor reservoir is emptied from extractor